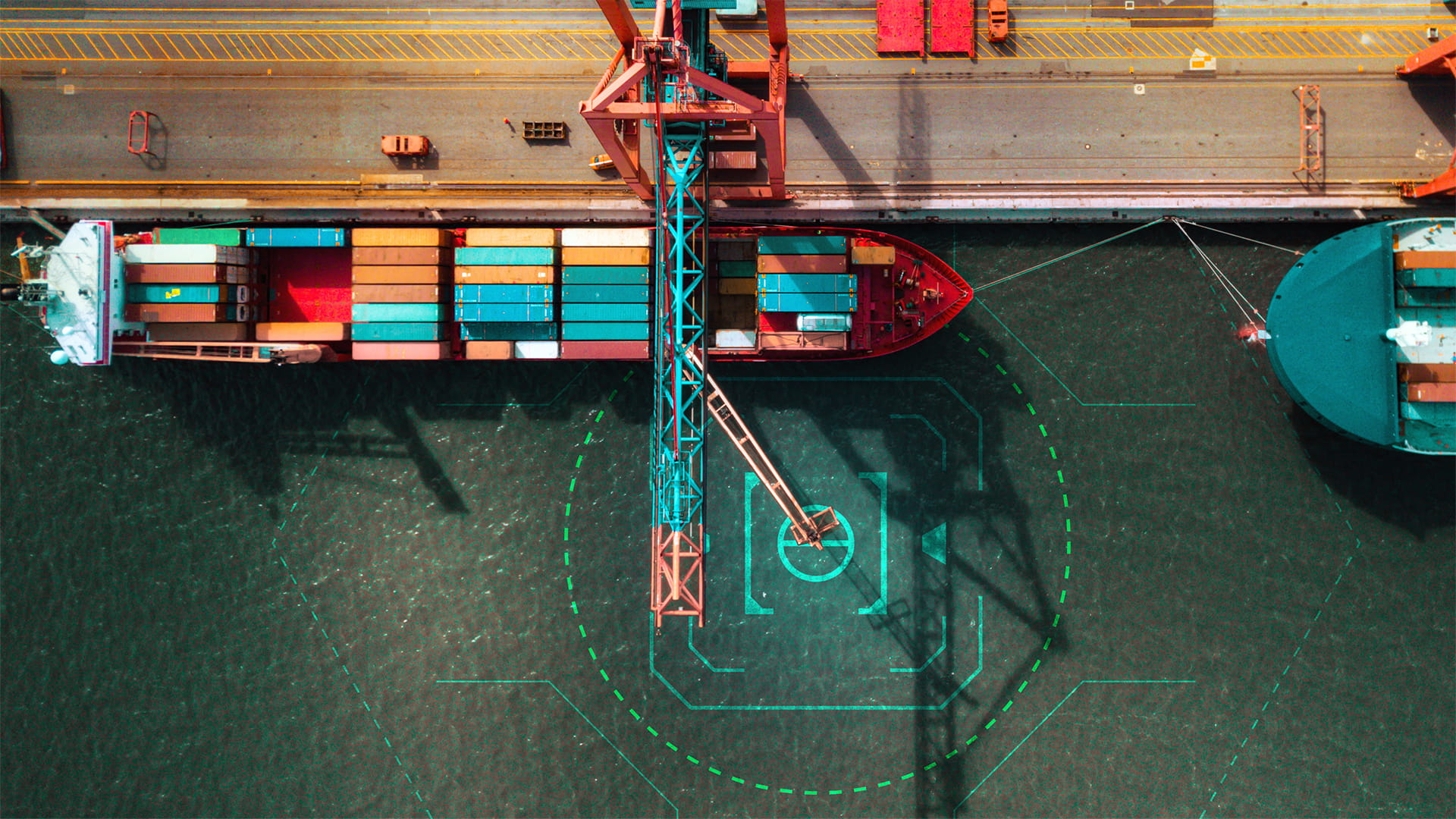

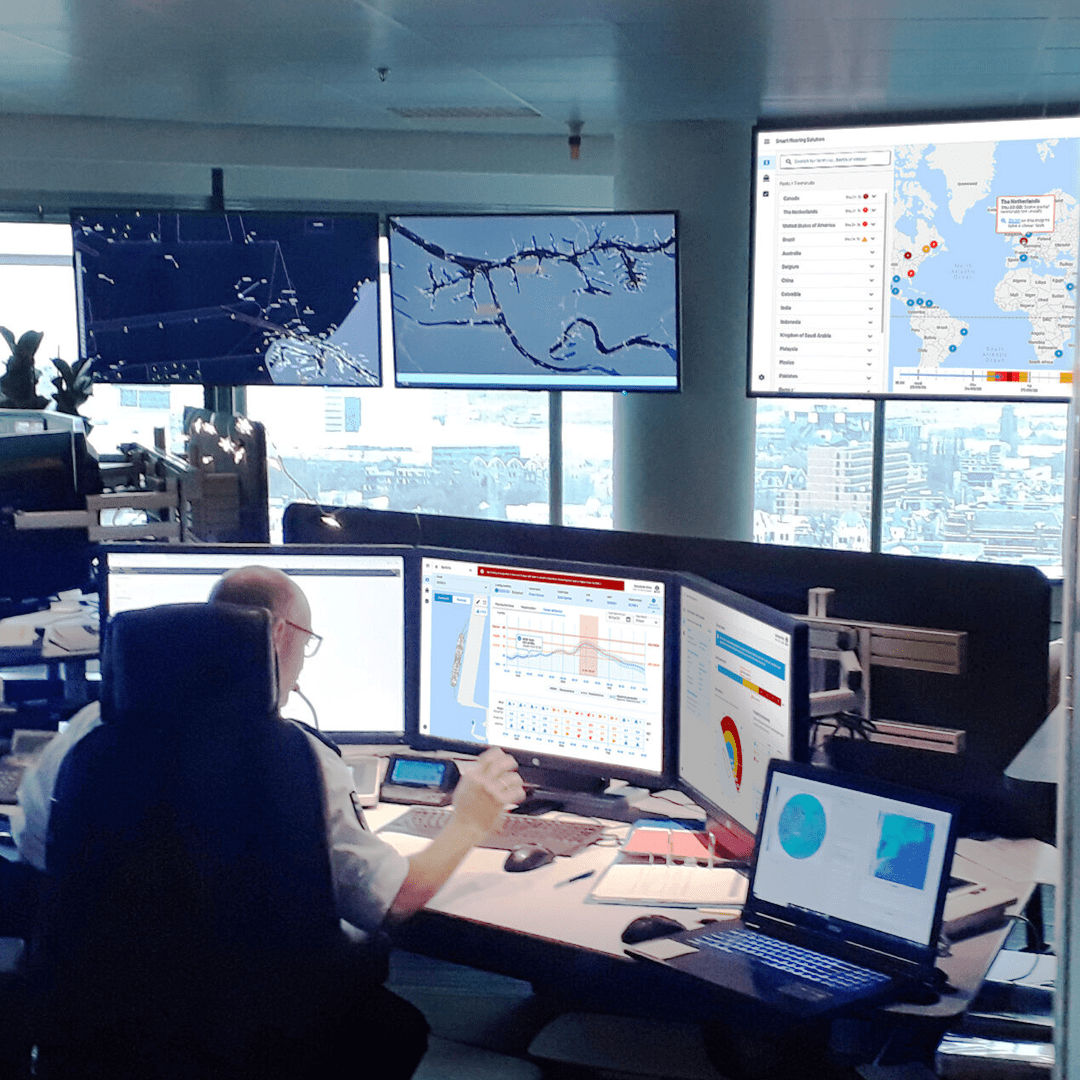

Smart mooring - maritime software solutions

For port authorities, terminal operators and shipping lines

Smart mooring solution app *Smart mooring solution app *

Increased operational safety

Increase the opportunity for timely action to maintain safe vessel operations

Improved vessel planning

Improve planning with real-time and predictive mooring analytics

Data-driven decision-making

Help operators and captains make more-informed decisionsWe create safer, smarter and more efficient ports

With a predictive decision support solution that uses real-time data and metocean forecasts to enhance vessel mooring and related operations. When it comes to mooring, each individual port, terminal, and individual berth has different safety and operational needs.With Smart Mooring, you can create the perfect overview, with decision-making for every berth on the map supported by the right levels of intelligence.

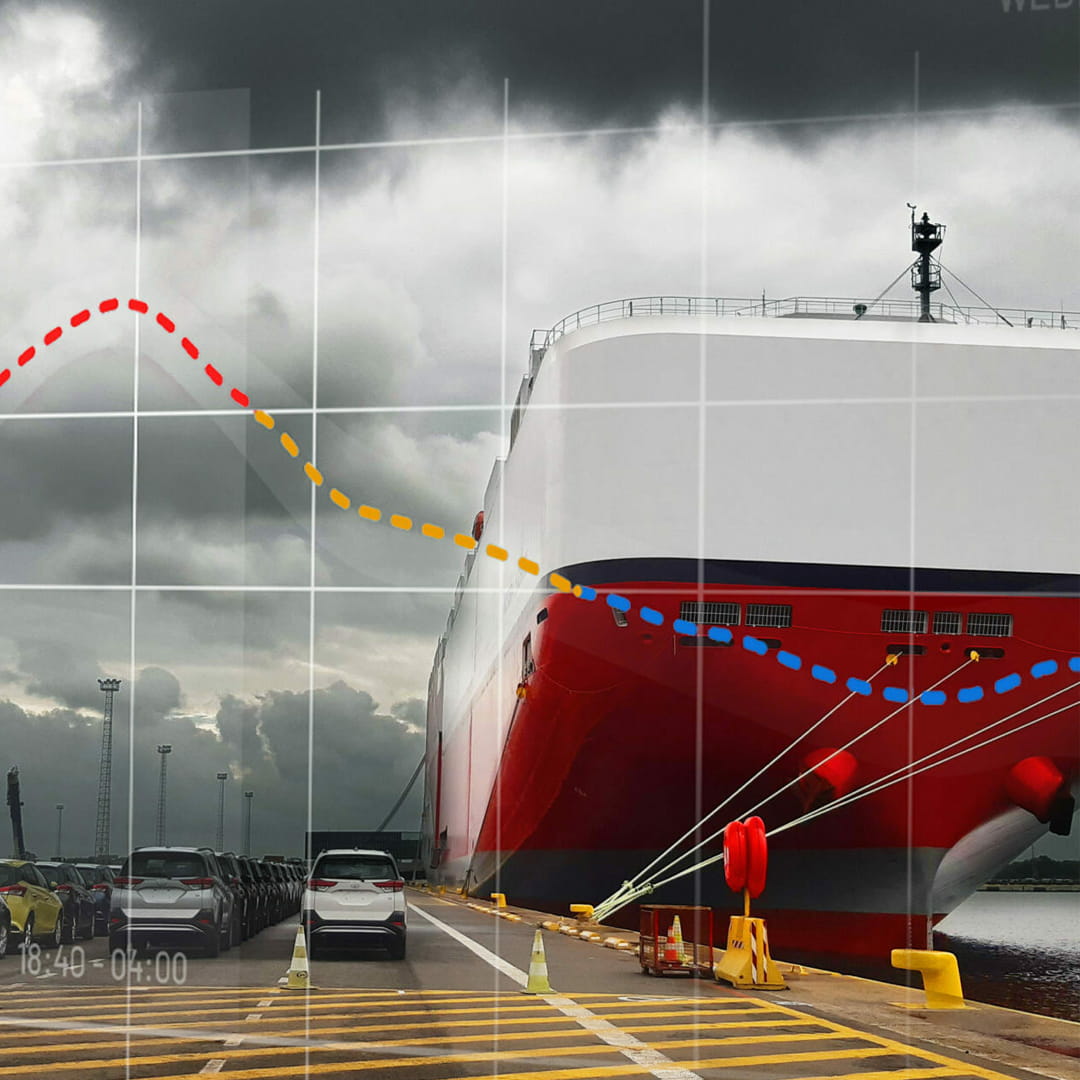

A digital twin of the

ship-shore interface

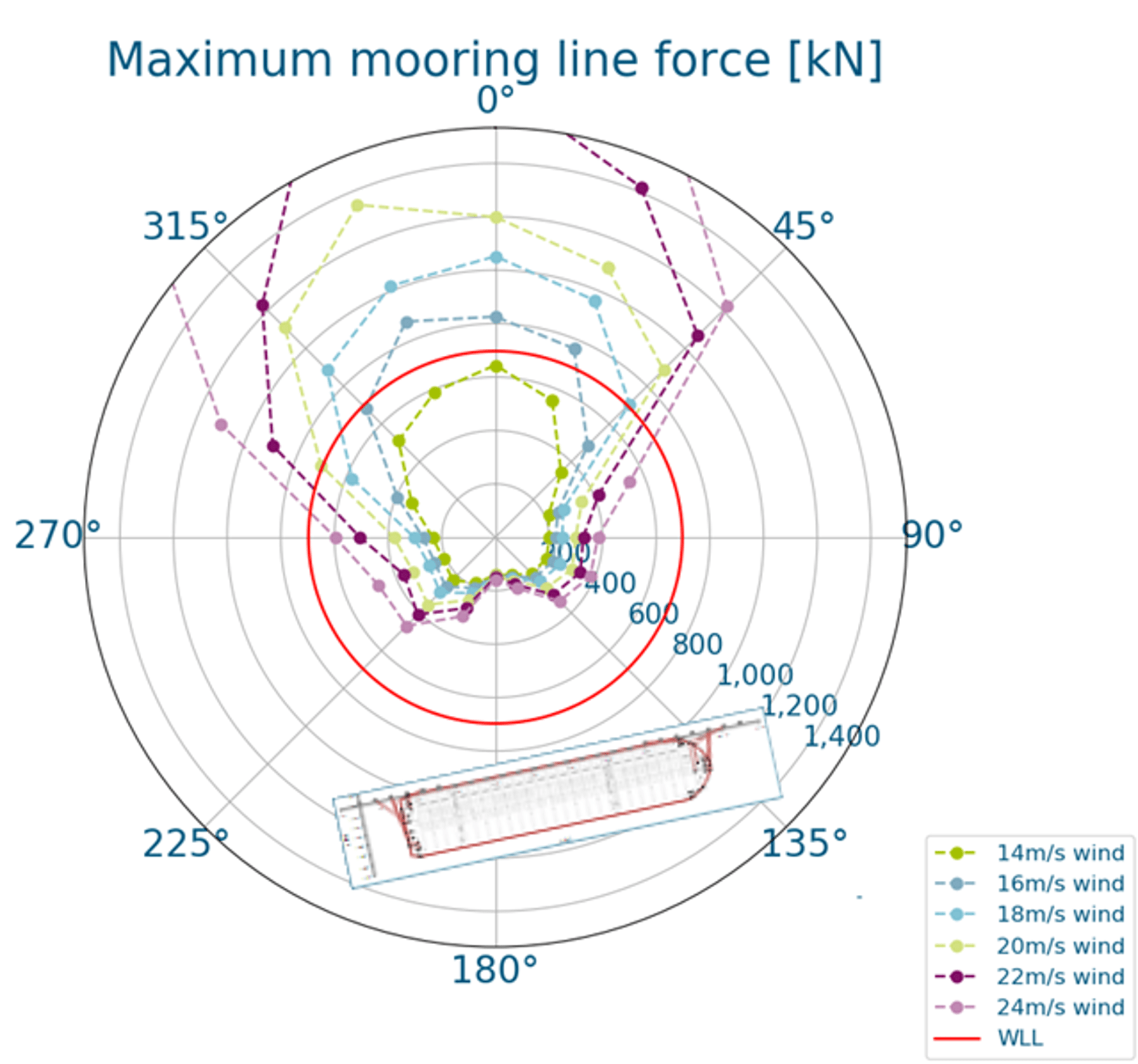

Driven by relevant data, a digital twin is a virtual mirror of a real-world asset, process or even an entire system, in this case the ship-shore interface. This mirror provides insight into how the interaction between ship and shore under a variety of simulated conditions, helping you to improve decision-making and optimise business processes.

More about the technology

Learn from our experts about the technological depth of Smart Mooring and how it is based on dynamic mooring analysis.

We innovate for you

We innovate with our key users in mind. We provide them real-time, predictive insights into unsafe mooring situations to help maintain control and boost operational efficiency.

Harbour Masters / Asset Managers

We provide harbour masters and asset managers an overview of unsafe and potentially risky mooring situations across the entire port, including vessel clearance requests.

Terminal Operators

For terminal operators, our solution provides insights into situations that could impact operational windows.

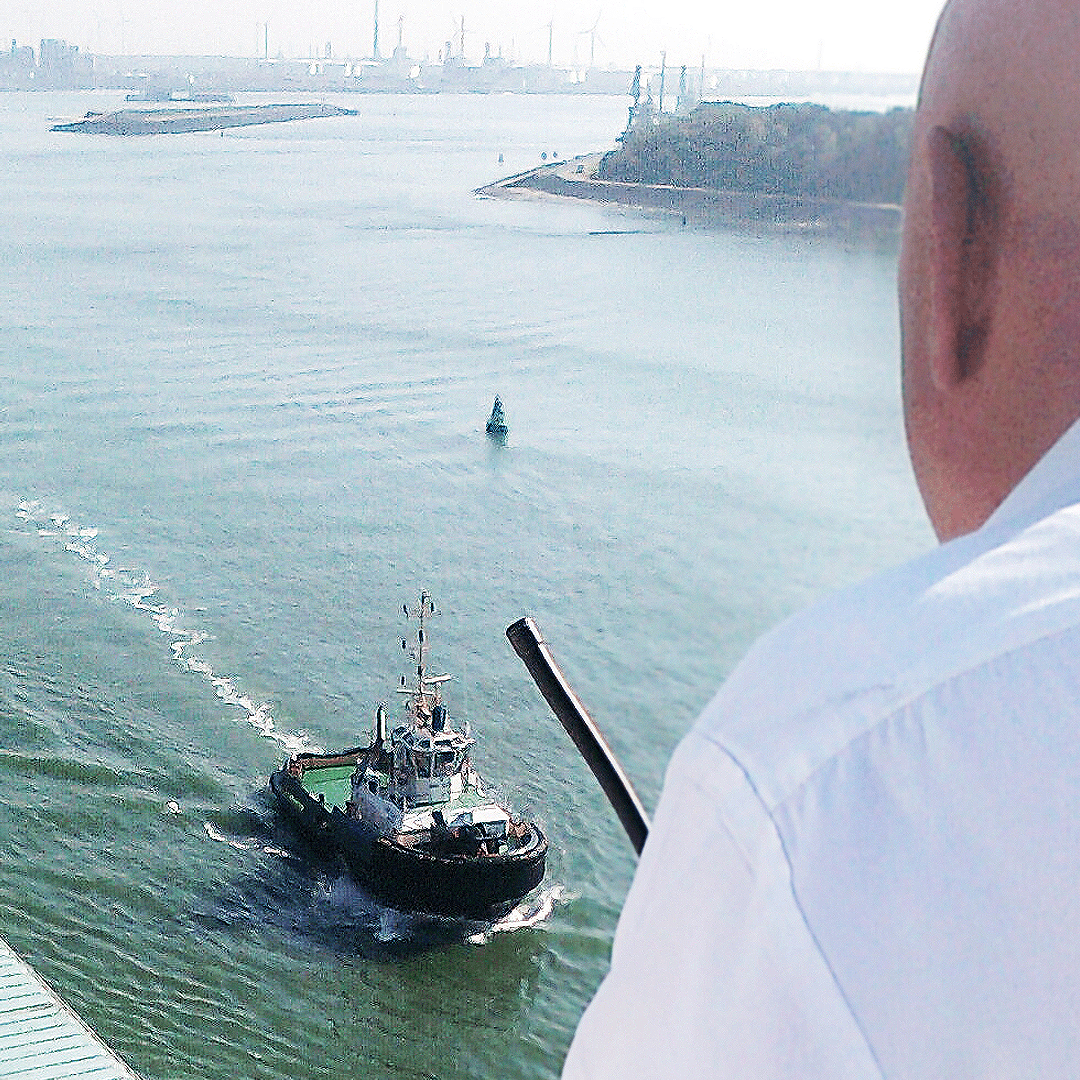

Shipping Liners

Our solution gives captains of shipping liners an extra pair of eyes for insight into unsafe mooring situations during cargo and vessel operations.

Cutting through the data and giving us actionable insights allows us to make decisions that keep our port moving.

Smart mooring and innovation

As your daily operations generate more and more data, it’s time to put it to good use. We combine your data, local environmental conditions, and decades of experience in ship hydrodynamics.

Goals

We're here to help our customers adapt to a very demanding future, helping them become safer, more data-driven, and more efficient.

Operations

Smart Mooring is easy to use and supports everyday decision-making, so our comprehensive analysis is available for everyone who needs it.

Value for money

We help our customers maximise their investment by applying intelligence where it adds the most value.

Seeing is believing

To embrace a new way of working, people need to understand the added value the new technology can offer them- and we can help you build this motivation, one step at a time.

It’s fascinating, because until you engage with technology, you don’t know how better informed your decisions could be. This software provides an opportunity to mitigate risks and maintain operational efficiency with support from a digital solution, rather than investing in additional quay furniture and very much aligns with our smart port strategy.